Since carbon footprint is a pressing concern, we will re-publish, and bring into one place here on our blog – the astounding facts about fabric and carbon footprint. You can easily lighten your carbon footprint just through your textile choices! Next week, we’ll re-publish graphs that visually and profoundly illustrate the facts.

The following article appeared in the June, 2009 issue of The O’Mama Report, a publication of the Organic Trade Association. Patty has made minor revisions in 2023.

Leigh and I had / have a bad tendency to bury the important takeaways among too much data – so I have bolded the important summary takeaways in case you are in a hurry!

Elephant In The Room!!

Although most of the current focus on lightening our carbon footprint revolves around transportation and heating issues, the modest little fabric all around you turns out to be from an industry with a gigantic carbon footprint. The textile industry, according to the U.S. Energy Information Administration, is the 5th largest contributor to CO2 emissions in the United States, after primary metals, nonmetallic mineral products, petroleum, and chemicals.[1]

The textile industry is huge, and it is a huge producer of greenhouse gasses (GHG’s). Today’s textile industry is one of the largest sources of GHG’s on Earth, due to the huge size.[2] In 2008, annual global textile production was estimated at 60 billion kilograms ( 60,000 Kilotons) of fabric. (In 2023, it’s 110,000 kilotons!) The estimated energy and water needed to produce that amount of fabric boggles the mind. (This is based on the old 2008 volume):

- 1,074 billion kWh of electricity or 132 million metric tons of coal and

- between 6 – 9 trillion liters of water[3]

Fabrics are the elephant in the room. They’re all around us – but no one is thinking about them. We simply overlook fabrics, maybe because they are almost always used as a component in a final product that seems rather innocuous: sheets, blankets, sofas, curtains, and of course clothing. Textiles, including clothing, accounted for about one ton of the 19.8 tons of total CO2 emissions produced by each person in the U.S. in 2006. [4] By contrast, a person in Haiti produced a total of only 0.21 tons of total carbon emissions in 2006.[5]

Your textile choices DO make a difference, so it’s vitally important to look beyond thread counts, color, and abrasion results.

We go onto evaluate the carbon footprint of fabrics made from various fiber types. You can read it all below or just look at the very high level take aways just below.

The big take-aways:

Any natural fiber fabric is a MUCH better carbon footprint choice than any synthetic fiber fabric.

Not only is the quantity of greenhouse gas (GHG) emissions of concern regarding synthetics, so too are the kinds of gasses produced during production of synthetic fibers. Nylon, for example, creates emissions of N2O, which is 300 times more damaging than CO2 [6] and which, because of its long life (120 years) can reach the upper atmosphere and deplete the layer of stratospheric ozone, which is an important filter of UV radiation. In fact, during the 1990s, N2O emissions from a single nylon.

Natural fibers, in addition to having a smaller carbon footprint, have additional benefits such as being able to sequester carbon and to biodegrade.

Substituting organic fibers for conventionally grown natural fibers is not just a little better – it is lots better in all respects: uses less energy for production, emits fewer greenhouse gases, and supports organic farming (which has myriad environmental, social and health benefits).

Organic agriculture is an undervalued and underestimated climate change tool that could be one of the most powerful strategies in the fight against global warming.

An organic fiber fabric, processed to GOTS standards, is, without a doubt), the safest, most responsible choice possible in terms of both stewardship of the earth, preserving health and limiting toxicity load to humans and animals, and reducing carbon footprint – and emphasizing rudimentary social justice issues such as no child labor.

OKAY, the above is my attempt at summarizing for busy people. The whole article with supporting studies and data continues below:

How do you determine the carbon footprint in any fabric?

Look at the “embodied energy’ in the fabric – that is, all of the energy used at each step of the process needed to create that fabric. To estimate the embodied energy in any fabric it’s necessary to add the energy required in two separate fabric production steps.

(1) Find out what the fabric is made from, because the type of fiber tells you a lot about the energy needed to make the fibers used in the yarn. The carbon footprint of various fibers varies a lot, so start with the energy required to produce the fiber.

(2) Next, add the energy used to weave those yarns into fabric. Once any material becomes a “yarn” or “filament”, the amount of energy and conversion process to weave that yarn into a textile is pretty consistent, whether the yarn is wool, cotton, nylon or polyester.[7]

Let’s look at #1 first: the energy needed to make the fibers and create the yarn. For ease of comparison we’ll divide the fiber types into “natural” (from plants, animals and less commonly, minerals) and “synthetic” (man made).

For natural fibers you must look at field preparation, planting, and field operations (mechanized irrigation, weed control, pest control, and fertilizers (manure vs. synthetic chemicals)), harvesting and yields. Synthetic fertilizer use is a major component of the high cost of conventional agriculture: making just one ton of nitrogen fertilizer emits nearly 7 tons of CO2 equivalent greenhouse gases.

For synthetics, a crucial fact is that the fibers are made from fossil fuels. Very high amounts of energy are used in extracting the oil from the ground as well as in the production of the polymers.

A study done by the Stockholm Environment Institute on behalf of the BioRegional Development Group concludes that the energy used (and therefore the CO2 emitted) to create 1 ton of spun fiber is much higher for synthetics than for hemp or cotton:

| KG of CO2 emissions per ton of spun fiber: | |||

| crop cultivation | fiber production | TOTAL | |

| polyester USA | 0.00 | 9.52 | 9.52 |

| cotton, conventional, USA | 4.20 | 1.70 | 5.89 |

| hemp, conventional | 1.90 | 2.15 | 4.10 |

| cotton, organic, India | 2.00 | 1.80 | 3.75 |

| cotton, organic, USA | 0.90 | 1.45 | 2.35 |

The table above only gives results for polyester; other synthetics have more of an impact: acrylic is 30% more energy intensive in its production than polyester [8] and nylon is even higher than that.

Not only is the quantity of GHG emissions of concern regarding synthetics, so too are the kinds of gasses produced during production of synthetic fibers. Nylon, for example, creates emissions of N2O, which is 300 times more damaging than CO2 [9] and which, because of its long life (120 years) can reach the upper atmosphere and deplete the layer of stratospheric ozone, which is an important filter of UV radiation. In fact, during the 1990s, N2O emissions from a single nylon plant in the UK were thought to have a global warming impact equivalent to more than 3% of the UK’s entire CO2 emissions.[10] A study done for the New Zealand Merino Wool Association shows how much less total energy is required for the production of natural fibers than synthetics:

| Embodied Energy used in production of various fibers: | |

| energy use in MJ per KG of fiber: | |

| flax fibre (MAT) | 10 |

| cotton | 55 |

| wool | 63 |

| Viscose | 100 |

| Polypropylene | 115 |

| Polyester | 125 |

| acrylic | 175 |

| Nylon | 250 |

SOURCE: “LCA: New Zealand Merino Wool Total Energy Use”, Barber and Pellow,

http://www.tech.plym.ac.uk/sme/mats324/mats324A9%20NFETE.htm

Natural fibers, in addition to having a smaller carbon footprint in the production of the spun fiber, have many additional benefits:

- Being able to be degraded by microorganisms and composted (improving soil structure); in this way the fixed CO2 in the fiber will be released and the cycle closed. Synthetics do not decompose: in landfills they release heavy metals and other additives into soil and groundwater. Recycling requires costly separation, while incineration produces pollutants – in the case of high density polyethylene, 3 tons of CO2 emissions are produced for every 1 ton of material burnt.[11] Left in the environment, synthetic fibers contribute, for example, to the estimated 640,000 tons of abandoned fishing nets in the world’s oceans.

- Sequestering carbon. Sequestering carbon is the process through which CO2 from the atmosphere is absorbed by plants through photosynthesis and stored as carbon in biomass (leaves, stems, branches, roots, etc.) and soils. Jute, for example, absorbs 2.4 tons of carbon per ton of dry fiber.[12]

Substituting organic fibers for conventionally grown fibers is not just a little better – it is lots better in all respects: uses less energy for production, emits fewer greenhouse gases, and supports organic farming (which has myriad environmental, social and health benefits). A study published by Innovations Agronomiques (2009) found that 43% less GHG are emitted per unit area under organic agriculture than under conventional agriculture.[13] A study done by Dr. David Pimentel of Cornell University found that organic farming systems used just 63% of the energy required by conventional farming systems, largely because of the massive amounts of energy requirements needed to synthesize nitrogen fertilizers. Further it was found in controlled long term trials that organic farming adds between 100-400kg of carbon per hectare to the soil each year, compared to non-organic farming. When this stored carbon is included in the carbon footprint, it reduces the total GHG even further.[14] The key lies in the handling of organic matter (OM): because soil organic matter is primarily carbon, increases in soil OM levels will be directly correlated with carbon sequestration. While conventional farming typically depletes soil OM, organic farming builds it through the use of composted animal manures and cover crops.

Taking it one step further beyond the energy inputs we’re looking at, which help to mitigate climate change, organic farming helps to ensure other environmental and social goals:

- eliminates the use of synthetic fertilizers, pesticides and genetically modified organisms (GMOs) which is not only an improvement in human health and agrobiodiversity but also for the associated off farm biotic communities

- conserves water (making the soil more friable so rainwater is absorbed better – lessening irrigation requirements and erosion)

- ensures sustained biodiversity

- and compared to forests, agricultural soils may be a more secure sink for atmospheric carbon, since they are not vulnerable to logging and wildfire.

Organic agriculture is an undervalued and underestimated climate change tool that could be one of the most powerful strategies in the fight against global warming, according to Paul Hepperly, Rodale Institute Research Manager. The Rodale Institute Farming Systems Trial (FST) soil carbon data (which covers 30 – now 45 years) shows conclusively that improved global terrestrial stewardship–specifically including regenerative organic agricultural practices–can be the most effective currently available strategy for mitigating CO2 emissions. (http://www.rodaleinstitute.org/files/Rodale_Research_Paper-07_30_08.pdf

At the fiber level it is clear that synthetics have a much bigger footprint than does any natural fiber, including wool or conventionally produced cotton. So in terms of the carbon footprint at the fiber level, any natural fiber beats any synthetic – at this point in time. Best of all is an organic natural fiber.

And next let’s look at #2, the energy needed to weave those yarns into fabric.

There is no dramatic difference in the amount of energy needed to weave fibers into fabric depending on fiber type.[15] The processing energy the cost is close to the same whether the fiber is nylon, cotton, hemp, wool, or polyester: thermal energy required per meter of cloth is 4,500-5,500 Kcal and electrical energy required per meter of cloth is 0.45-0.55 kwh. [16] This translates into huge quantities of fossil fuels – both to create energy directly needed to power the mills, produce heat and steam, and power air conditioners, as well as indirectly to create the many chemicals used in production. In addition, the textile industry has one of the lowest efficiencies in energy utilization because it is largely antiquated.

But there is an additional dimension to consider during processing: environmental pollution. Conventional textile processing is highly polluting:

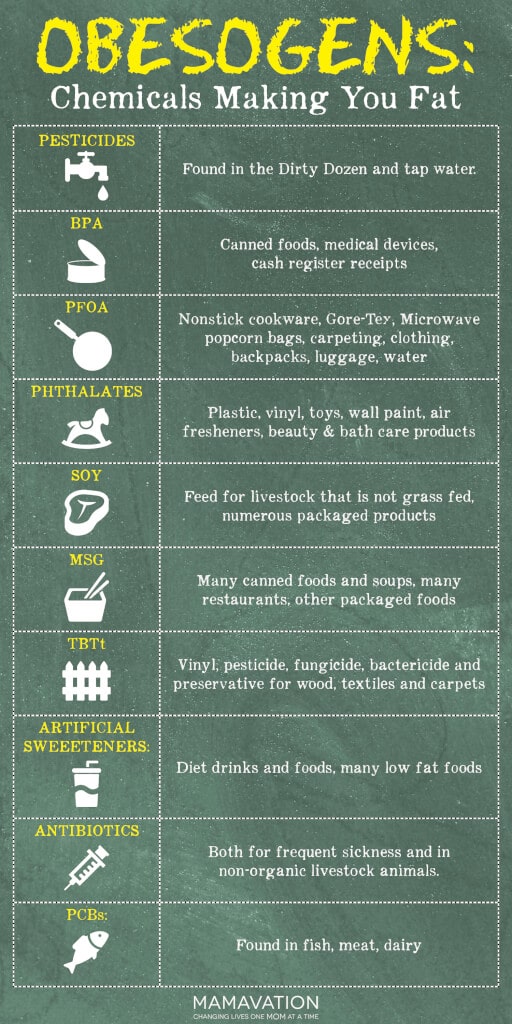

- 2000 chemicals are regularly used in textile processing, many of them known to be harmful to human (and animal) health. More are added frequently. Some of these chemicals evaporate, some are dissolved in treatment water which is discharged to our environment, and some remain in the fabric, to be brought into our homes (where, with use, tiny bits abrade and you ingest or inhale them). A whole list of the most commonly used chemicals in fabric production are linked to human health problems that vary from annoying to profound.

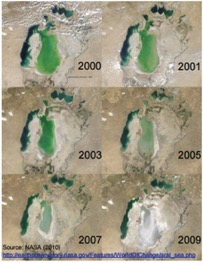

- The application of these chemicals uses copious amounts of water. In fact, the textile industry is the #1 industrial polluter of fresh water on the planet.[17] These wastewaters are discharged (largely untreated) into our groundwater with a high pH and temperature as well as chemical load. This fact will eventually kill all the local flora and fauna. Google the Aral Sea.

Currently, there are few regulatory standards for textiles in the United States. Many European countries, as well as Japan and Australia, have much stricter restrictions on the use of chemicals in textiles and apparel than does the United States, and these world regulations will certainly impact U.S. production.

There is a bright spot in all this: an alternative to conventional textile processing does exist. The new (GOTS had just been promulgated when this article first appeared in 2009) Global Organic Textile Standard (GOTS) (www.global-standard.org)

is a tool for an international common understanding of environmentally friendly production systems and social accountability in the textile sector. GOTS addresses issues in the production, processing, manufacturing, packaging, labeling, exportation, importation, and distribution of all natural fibers; that means, specifically, for example: use of certified organic fibers, prohibition of all GMOs and their derivatives; and prohibition of a long list of synthetic chemicals (for example: formaldehyde and aromatic solvents are prohibited; dyestuffs must meet strict requirements (such as threshold limits for heavy metals, no AZO colorants or aromatic amines) and PVC cannot be used for packaging).

A fabric which is produced to the GOTS standards is more than just the fabric.

It is a promise to keep our air and water pure and our soils renewed. It’s a fabric which will not cause harm to you or your descendants.

At this point in time, given the technology we have now, an organic fiber fabric, processed to GOTS standards, is, without a doubt), the safest, most responsible choice possible in terms of both stewardship of the earth, preserving health and limiting toxicity load to humans and animals, and reducing carbon footprint – and emphasizing rudimentary social justice issues such as no child labor.

So INSIST on GOTS certified fabrics. There is no time to lose. What you buy will get produced.

[1] Source: Energy Information Administration, Form EIA:848, “2002 Manufacturing Energy Consumption Survey,” Form EIA-810, “Monthly Refinery Report” (for 2002) and Documentatioin for Emissions of Greenhouse Gases in the United States 2003 (May 2005). http://www.eia.doe.gov/emeu/aer/txt/ptb1204.html

[2] Dev, Vivek, “Carbon Footprint of Textiles”, April 3, 2009, http://www.domain-b.com/environment/20090403_carbon_footprint.html

[3] Rupp, Jurg, “Ecology and Economy in Textile Finishing”, Textile World, Nov/Dec 2008

[4] Rose, Coral, “CO2 Comes Out of the Closet”, GreenBiz.com, September 24, 2007

[5] U.S. Energy Information Administration, “International Energy Annual 2006”, posted Dec 8, 2008.

[6] “Tesco carbon footprint study confirms organic farming is energy efficient, but excludes key climate benefit of organic farming, soil carbon”, Prism Webcast News, April 30, 2008, http://prismwebcastnews.com/2008/04/30/tesco-carbon-footprint-study-confirms-organic-farming%E2%80%99s-energy-efficiency-but-excludes-key-climate-benefit-of-organic-farming-%E2%80%93-soil-carbon/

[7] Many discussions of energy used to produce fabrics or final products made from fabrics (such as clothing) take the “use” phase of the article into consideration when evaluating the carbon footprint. The argument goes that laundering the blouse (or whatever) adds considerably to the final energy tally for natural fibers, while synthetics don’t need as much water to wash nor as many launderings. We do not take this component into consideration because

- it applies only to clothing; even sheets aren’t washed as often as clothing while upholstery is seldom cleaned.

- is biodegradeable detergent used?

- Is the washing machine used a new low water machine? Is the water treated by a municipal facility?

- Synthetics begin to smell if not treated with antimicrobials, raising the energy score.

Indeed, it’s important to evaluate the sponsors of any published studies, because the studies done which evaluate the energy used to manufacture fabrics are often sponsored by organizations which might have an interest in the outcome. Additionally, the data varies quite a bit so we have adopted the values which seem to be agreed upon by most studies.

[8] Ibid.

[9] “Tesco carbon footprint study confirms organic farming is energy efficient, but excludes key climate benefit of organic farming, soil carbon”, Prism Webcast News, April 30, 2008, http://prismwebcastnews.com/2008/04/30/tesco-carbon-footprint-study-confirms-organic-farming%E2%80%99s-energy-efficiency-but-excludes-key-climate-benefit-of-organic-farming-%E2%80%93-soil-carbon/

[10] Fletcher, Kate, Sustainable Fashion and Textiles, Earthscan, 2008, Page 13

[11] “Why Natural Fibers”, FAO, 2009: http://www.naturalfibres2009.org/en/iynf/sustainable.html

[12] Ibid.

[13] Aubert, C. et al., (2009) Organic farming and climate change: major conclusions of the Clermont-Ferrand seminar (2008) [Agriculture biologique et changement climatique : principales conclusions du colloque de Clermont-Ferrand (2008)]. Carrefours de l’Innovation Agronomique 4. Online at <http://www.inra.fr/ciag/revue_innovations_agronomiques/volume_4_janvier_2009>

[14] International Trade Centre UNCTAD/WTO and Research Institute of Organic Agriculture (FiBL); Organic Farming and Climate Change; Geneva: ITC, 2007.

[15] 24th session of the FAO Committee on Commodity Problems IGG on Hard Fibers of the United Nations

[16] “Improving profits with energy-efficiency enhancements”, December 2008, Journal for Asia on Textile and Apparel, http://textile.2456.com/eng/epub/n_details.asp?epubiid=4&id=3296

[17] Cooper, Peter, “Clearer Communication,” Ecotextile News, May 2007.